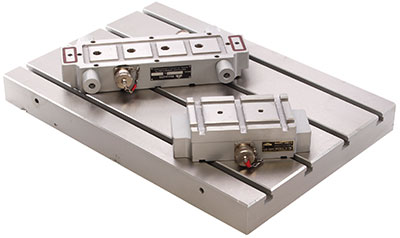

Description

Features

- Patented design with full steel working face.

- Unique self clamping magnets.

- Ergonomic design and light weight magnet modules.

- Magnets can be Daisy Chain connected so that only one cable needs to be connected to the controller and the magnets are connected amongst themselves.

- Mangets clamps to the machine bed without the need of any external clamping simultaneously clamping the job.

- Magnets can easily be placed where required.

- Any module of the magnet can be used to switch ON/ OFF as all the modules are interconnected with detachable connectors. This gives a great deal of flexibility.

- Height of all magnets is 60 mm.

- Clamping force for DoubleMag 50 ≥ 300 kg/ pole.

- Clamping force for DoubleMag 75 ≥ 675 kg/ pole.