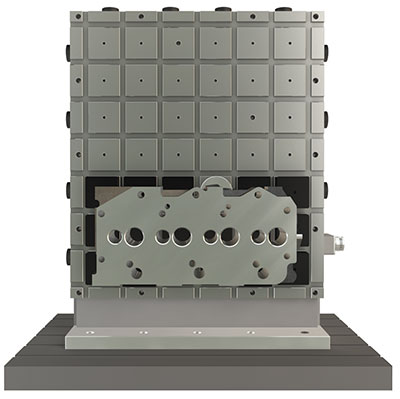

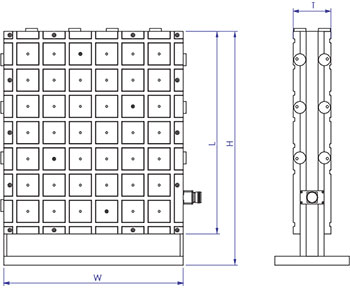

Description

Features

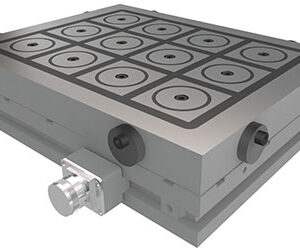

- Patented full steel Top surface.

- High induction of magnetic flux.

- High & uniform clamping power throughout the bed.

- Variable magnetic power possible.

- Perfect safety in case of power failure.

- 2 or 4 or multiple magnetic face.

- Unobstructed movement of tools during machining as all five faces of the job can be machined in the same setting.

- Drastically reduces the setup time and machining of the work pieces.

- Total magnetic surface used for clamping giving better machining accuracy as reducing chattering.

- 100% Leak Proof.

- Clamping force for EPCUBE 50 ≥ 350 kg/ pole.

- Clamping force for EPCUBE 75 ≥ 790 kg/ pole.