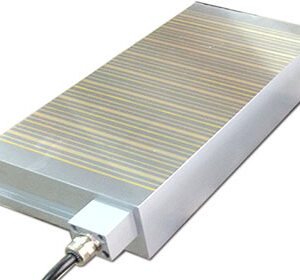

Description

Features

- Magnetic power above 100 MT/m2.

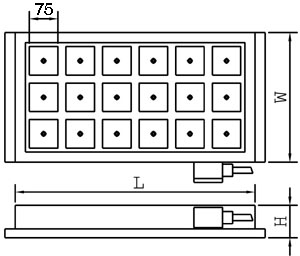

- Magnetic Pole Size: 75 x 75 mm.

- Perfect safety in case of power failure. No electricity needed to Keep the Electro Permanent Magnetic Chuck ON.

- Unobstructed movement of cutters during machining.

- Variable magnetic power.

- Drastically reduces set up Time by using magnets.

- Achieves best machining accuracy.

- Uniform clamping over entire area, such no chattering of tools there by improving finish and tool life.

- Reduce Clamping/ De-clamping time in CNC machines drastically resulting in increased production.